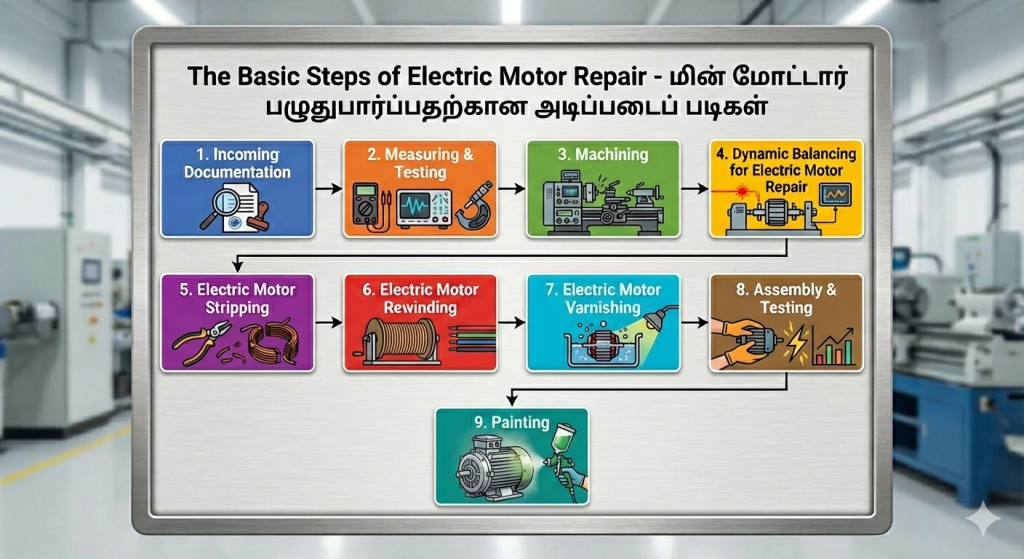

The Basic Steps of Electric Motor Repair Process

Electric motors play a critical role in industrial, commercial, and manufacturing operations. Continuous operation, electrical stress, heat, and mechanical wear can gradually reduce motor efficiency and reliability. A professional Electric Motor Repair process helps restore performance, minimize downtime, and extend the overall service life of the motor.

1. Incoming Documentation

The electric motor repair process begins with proper incoming documentation. When a motor arrives at the repair facility, all technical and operational details are carefully recorded.

This includes motor specifications such as horsepower, voltage, RPM, frame size, and application details. Customer-reported issues and operating conditions are also documented. Accurate documentation ensures traceability, quality control, and effective communication throughout the repair process.

2. Measuring & Testing

Before dismantling the motor, comprehensive measuring and testing is performed to identify electrical and mechanical faults. Common diagnostic tests include insulation resistance testing, winding resistance measurement, continuity checks, and preliminary bearing inspection.

These tests help determine whether the motor requires rewinding, mechanical correction, or preventive maintenance, allowing for an accurate repair plan.

3. Machining

Machining is a crucial step in electric motor repair, especially when mechanical components show signs of wear or damage. During this stage, parts such as shafts, bearing seats, and end shields are inspected and corrected using precision machining techniques. Proper machining restores correct tolerances, ensures alignment, and prevents vibration-related failures during operation.

4. Dynamic Balancing for Electric Motor Repair

Dynamic balancing is essential for maintaining smooth and stable motor operation. Any imbalance in the rotor can cause excessive vibration, noise, and premature bearing failure. Professional dynamic balancing for electric motors ensures that rotating components operate evenly at all speeds. This process significantly improves motor reliability, efficiency, and long-term performance, particularly in high-speed and heavy-duty applications.

5. Electric Motor Stripping

After initial testing and machining, the motor is carefully dismantled during the stripping stage. Old or damaged windings are removed, and the stator core is thoroughly cleaned.

Electric motor stripping must be performed with precision to avoid damage to the stator laminations. Proper stripping prepares the motor for high-quality rewinding and insulation replacement.

6. Electric Motor Rewinding

Electric motor rewinding is one of the most critical stages of the repair process. New windings are installed using high-quality copper conductors and approved insulation materials.

The original winding design, number of turns, and insulation class are maintained to ensure the motor regains its original efficiency, torque, and thermal performance. Correct rewinding plays a major role in extending motor life and improving energy efficiency.

7. Electric Motor Varnishing

Following rewinding, the stator undergoes varnish impregnation. This process strengthens the insulation system and protects the windings from environmental factors.

Electric motor varnishing improves resistance to moisture, dust, and heat while enhancing thermal conductivity. This step is essential for ensuring long-term reliability under demanding operating conditions.

8. Assembly and Testing

Once varnishing is complete, the motor is carefully reassembled. New bearings, seals, and hardware are installed, and all components are aligned to manufacturer specifications.

Final testing is conducted to verify electrical safety, vibration levels, noise, and overall performance under no-load and load conditions. This stage confirms that the electric motor repair meets industry standards and operational requirements.

9. Painting

The final stage of the electric motor repair process is painting and finishing. Industrial-grade coatings are applied to protect the motor from corrosion and environmental damage.

In addition to improving durability, proper painting enhances the professional appearance of the motor and supports easy identification in industrial environments.

A systematic electric motor repair process restores motor performance, improves efficiency, and significantly extends service life. Each stage—from inspection and testing to rewinding, balancing, and final testing—plays a vital role in ensuring reliable operation.